Why Use Asphera For Flat Optic Needs: Some Information About Fluoride Windows, Sapphire Windows, and Alpha Quartz Windows

Asphera windows offers high-quality LiF windows, sapphire windows, and alpha quartz products. Our innovative products are perfect for both residential and commercial properties. With over 35 years of experience, we are dedicated to providing our clients with the best possible service and products.

LiF Windows

Lithium fluoride (LiF) windows have been used extensively in the past to allow diagnostics to be placed in the target chamber to observe the shock wave as it propagates through the different materials. However, these windows have a relatively low melting point and are easily damaged by the high temperatures and pressures generated by the shock wave.

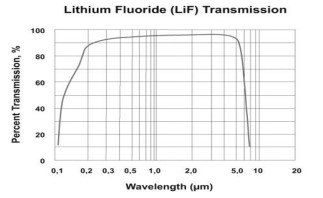

Lithium Fluoride windows are commonly used for optical components (windows, wedge windows, lenses, prisms) in a wide spectrum band from vacuum ultra-violet to infrared and is transparent over the entire range of 0.140μm to 7μm. It is used in fabricating first surface mirrors for CO2 lasers. The high transmission, low absorption, and stable physical and optical properties of lithium fluoride enable its use as a protective window over a wide range of environments, especially those that are chemically aggressive or erosive.

LiF crystals are optically isotropic and insoluable in water. They are resistant to most chemical reagents except for HF acids. The lithium fluoride window is often used as a viewport in high-pressure cells and reactors because of its resistance to attack by HF acid. Its refractive index is the lowest out of all common infrared materials. We offer micro-windows 1.6 mm diameters in thickness as low as 150um up to large 100 mm diameters and 50 mm thicknesses in (100) and (110) orientations.

Sapphire Windows

Sapphire windows are much more resistant to the high temperatures and pressures generated by shock waves, and can therefore be used to observe the shock wave more accurately. Sapphire is a single crystal form of aluminum oxide (Al2O3) that is transparent over a wide range of wavelengths from the ultraviolet to the infrared. It has a high melting point and is resistant to attack by most chemicals.

Sapphire windows are used in a variety of applications where high strength, thermal resistance, and optical transparency are required. They are often used as viewports in high-pressure cells and reactors because of their resistance to attack by HF acid. Sapphire windows can also be used in high-temperature environments and in applications where a wide range of wavelengths need to be transmitted.

We offer sapphire windows in a variety of sizes and thicknesses. Our standard sizes are 1.6 mm in diameter and 150 um thick, but we can also provide larger windows up to 100 mm in diameter and 50 mm thick.

Alpha Quartz Windows

Alpha quartz is also being considered as a potential window material for this application due to its high melting point and resistance to damage. Alpha quartz is a type of quartz that has a higher melting point and is more resistant to damage than other types of quartz. It is often used in high-temperature applications and in environments where a wide range of wavelengths need to be transmitted.

We offer alpha quartz windows in a variety of sizes and thicknesses. Our standard size is 1.6 mm in diameter and 150 um thick, but we can also provide larger windows up to 100 mm in diameter and 50 mm thick.

No matter what your needs are, we can help you find the right window material for your application. Contact us today to learn more about our products and services.

We have a simple promise to our customers: provide the highest quality product, turn it around fast, and do it at the lowest possible price. We offer customized pricing that meets your needs - not ours. Our management team has over 100 years of experience in the optical industry, and we’ll work hard every day to earn and keep your business. Your loyalty is our achievement.

Menu

STAY CONNECTED

Join our newsletter and find out more

Contact Us

We will get back to you as soon as possible

Please try again later

terms and conditions